The transformation of Valmet Automotive’s Uusikaupunki plant from a Saab car line to a future armoured-vehicle factory marks a new chapter in Finland’s industrial evolution: farewell, cars — welcome, armour.

When Patria Land Oy and Valmet Automotive Oyj announced their Letter of Intent (LOI) to cooperate on the manufacturing and testing of armoured vehicles, it was more than a standard industrial partnership. It signalled a strategic shift: the repurposing of Finland’s only high-volume car-assembly facility into a defence manufacturing asset.

Located in the coastal town of Uusikaupunki, the plant has built everything from Swedish Saabs to German Mercedes-Benz luxury cars. Now, it will apply that manufacturing capability to one of Europe’s key defence supply chains.

At DSEI 2025 in London, Patria and Babcock announced their partnership to build and support the Patria 6×6 armoured vehicle for the British Army. (Video: NDR)

Under the LOI, Patria’s Protected Mobility business – covering its 6 × 6, AMV XP 8 × 8, and TRACKX mounted platforms – will explore manufacturing and testing at the Valmet facility. This comes at a time when demand for armoured vehicles is surging across Europe, and local production capacity is becoming a strategic asset for defence-industrial resilience.

“Patria is focused on delivering to existing customers and boosting production capacity to meet rising demand for our armoured vehicles,” said Jussi Järvinen, Executive Vice-President of Protected Mobility at Patria, according to Patria’s press release.

“Our current production is sufficient for all existing orders; however, we are seeking additional capacity. Therefore, Patria is now considering a partnership also with Valmet Automotive.”

For Valmet Automotive, the LOI offers an opportunity to diversify beyond the automotive sector.

“This Letter of Intent with Patria on manufacturing and testing armoured vehicles is a concrete demonstration of the progress of our strategy extending beyond the automotive industry,” said Pasi Rannus, CEO of Valmet Automotive. “We are pleased that our expertise is in demand also in other industries that require high technological capabilities. This LOI is a major first step for us in contract manufacturing in the defence sector.”

This moment is also the culmination of more than half a century of industrial transformation — and tells a broader story about how manufacturing agility, strategic location and industrial reputation can pivot from cars to military vehicles.

A Nordic Industrial Experiment: Founding of the Uusikaupunki Plant

The first Finnish attempt to start mass car production came in 1961, when the state-owned industrial group Valmet held talks with Fiat about setting up an assembly plant in Finland. The negotiations led nowhere, but Valmet — already experienced in building aircraft, tractors and engines — continued to explore international partnerships.

During the 1960s, Valmet courted several foreign manufacturers, including Volvo, Saab, Renault, and the British Motor Corporation. The most promising talks were with Saab-Scania, which was completing its new Saab 99, a model Finnish engineers saw as having strong export potential.

When the Finnish Parliament in 1968 passed a tax-relief law to encourage investment in designated development regions, it effectively steered the new car plant to the country’s south-west coast. Uusikaupunki won the bid — its port offered the shortest sea route to Sweden.

The Swedish company Saab-Scania and Finland’s state-owned industrial group Valmet formed a joint venture to establish a car plant in Uusikaupunki. The new company, Saab-Valmet Oy, began operations on 13 November 1969, when the first car — a Saab 96 — rolled off the production line. The very first 96 was ceremonially presented to President Urho Kekkonen, and was later driven by the First Lady, Sylvi Kekkonen.

During the first full production year, 1970, the plant built 8,300 Saabs, rising to 12,300 the following year. Expansion in 1972 and 1974 lifted capacity to 18,000 and 30,000 cars a year, respectively.

Exports started almost immediately — 3,000 cars in 1970 and more than 7,000 in 1971 — mostly to Sweden, to prove that Finnish-built Saabs matched, or exceeded, the quality of their Swedish counterparts. Throughout the 1970s and 1980s, Uusikaupunki produced a wide range of Saab models: Saab 95, Saab 96, Saab 99, Saab 90, and later the Saab 900, including the iconic Saab 900 Cabriolet, built almost exclusively in Finland. The open-top 900 became a cult favourite in export markets, especially in its bright yellow livery.

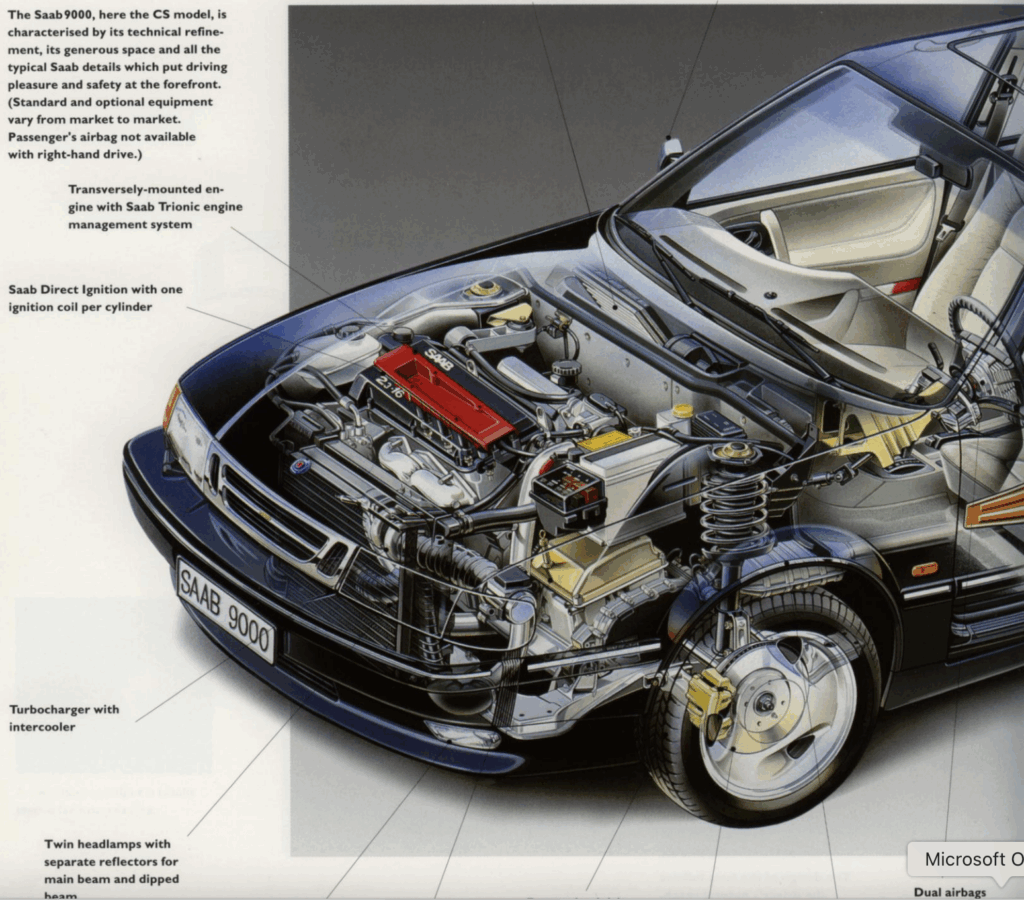

The Saab 9000 – Nordic Engineering with Italian Flair

The Saab 9000, launched in the mid-1980s, was developed as part of the Type Four joint platform with Italy’s Fiat Group. Its siblings were the Fiat Croma, Lancia Thema, and Alfa Romeo 164 — each aimed at a different market segment, from executive saloon to sports luxury.

While outwardly similar to the Croma and Thema, the Saab 9000 was substantially re-engineered for safety and export compliance. Saab reinforced the body structure to meet stringent US crash standards, redesigned the front for improved impact protection, and fitted heavier side beams. As a result, only seven parts were truly interchangeable with their Italian cousins.

The effort paid off. The 9000 was named Best Prestige Car of 1985 by L’Action Automobile and quickly became a symbol of Nordic reliability wrapped in Italian style.

In 1986, Saab put that reputation to the test. At Alabama’s Talladega Superspeedway, three 9000 Turbo 16s ran non-stop for 20 days and 20 nights, covering over 100,000 kilometres and setting 21 international and two world speed records. The event — branded “Saab Turbo: In the Long Run” — demonstrated the car’s endurance and engineering integrity.

To commemorate the feat, Saab released special Talladega Edition models, later revived in 1996 with the next-generation 900 — a lasting nod to the company’s fusion of Scandinavian engineering discipline and Italian design heritage.

Build Quality and Finnish Pride

Over the decades, the Uusikaupunki plant built a remarkable range of Saab models — and in many circles the cars built in Finland gained a reputation as the best-built Saab products, thanks to Finnish manufacturing discipline, high standards and contract focus.

Saab models built in Uusikaupunki include:

- Saab 95 (1969–1975) – The earliest model built in Finland, together with the 96. The station wagon version of 96. (2,833 built in Uusikaupunki)

- Saab 96 (1969–1980) — The first big hit. (65,887)

- Saab 99 (1969–1984) — Uusikaupunki produced 191,049 model 99s.

- Saab 900 (1978-1992) – (238,898).

- Saab Cabriolet (1986–2003). Popular in the US market. (198,032)

- Saab 9000 (1986–1990) – the luxury model. (8,267)

- Saab 90 (1984-1987) — a model created exclusively in Uusikaupunki, combining the front of 99 with the rear of 900 (25,380).

- Saab 9-3 (1999–2003). Only 7,789 were built in Uusikaupunki.

Total Saab Production in Uusikaupunki (1969–2003): 738,135 cars.

The Saab 900 Cabriolet (convertible) models were built at this plant — indeed, many enthusiasts note that all Saab 900/9-3 Cabriolets from 1986 to 2003 were produced at Uusikaupunki, Finland by Valmet.

In 2019, to mark the 50th anniversary of manufacturing in Uusikaupunki, Valmet Automotive published a summary of its heritage:

“The first car at the Uusikaupunki car plant was completed on 13 November 1969, at 6 am … The Uusikaupunki car plant remains the heart of the company.” This era cemented two hallmarks of the plant: contract manufacturing for established OEMs – rather than in-house brand building – and a reputation for quality. For analysts of defence manufacturing, these traits turn out to be valuable in transitioning to armoured-vehicle production.

Diversification into Contract Manufacturing: Talbots, Opels, Lada…

As Saab’s volumes slowed and industry conditions changed, the Uusikaupunki plant shifted into other contract manufacturing roles. In the late 1970s and 1980s the facility began assembling cars for other brands: for example, the Talbot Horizon and other Chrysler/Talbot/PSA models.

Later, during the 1990s, the plant built the Opel Calibra (1991-1997) and Lada EuroSamara (1996-1998) among others. While such volumes were modest relative to major OEMs, the model of “contract manufacturer” rather than brand owner took hold. Ultimately, Valmet became the sole owner (from 1992) and renamed the company Valmet Automotive in 1995.

This period established the plant’s adaptability: different brands, different platforms, and increasingly a reputation for flexibility and engineering competence.

- Talbot 1510/Solara (1979–1985) 14,047 cars

- Talbot Horizon (1979–1985) 17,931 cars

- Opel Calibra (1991–1997) 93,978 cars

- Lada EuroSamara (1996–1998) 14,048 cars

Premium Contract Era: Porsche and Mercedes-Benz

In 1997, the Uusikaupunki plant entered its most high-profile phase with Porsche. The plant signed a contract to build the Porsche Boxster — a major leap from mass-market models.

Over the years, the plant built many thousands of Boxsters and Caymans for Porsche, gaining deep experience in premium volumes, complex processes and high-quality demands.

In July 2012, a major contract was announced: Valmet Automotive would build the Mercedes-Benz A-Class at Uusikaupunki starting in 2013.

In 2017, the plant also took on the Mercedes-Benz GLC compact SUV production under contract.

At the height of this era, the plant employed over 4,000 people and was widely regarded as one of the most efficient in Mercedes’ global contract-manufacturing network. Finnish and automotive-industry commentary frequently made a claim that the Uusikaupunki plant was “the most efficient” plant manufacturing MB cars — citing low labour cost in Finland relative to Germany, strong automation, and stable workforce. Yet here lay a strategic vulnerability: contract manufacturing for premium OEMs depends heavily on global allocation decisions, platform lifecycles, OEM strategy and long lead times. Silicon-age disruption, such as EVs and autonomous tech, trade-shifts (EU/US, China), and supply-chain pressures combined to weaken the outlook.

- TH!NK city (2009–2011), Norwegian electric car (1,794 cars)

- Garia (2009–2011), a golf car (2,192 cars)

- Fisker Karma (2011–2012), a hybrid sports car (2,000)

- Lightyeaer 0 (2022–2023), a luxury electric car (around ten)

Concept Cars Built in Uusikaupunki

- Saab 9000 Cabriolet

- Opel Calibra Cabriolet

- Audi A4 Cabriolet

- Ford Thunderbird hardtop coupe[83]

- Garia LSV

- Eva electric city car

- Talbot Horizon limousine

The Downturn: End of Car Volumes

By the early 2020s, the global automotive industry was undergoing a dramatic transformation: electrification, digitalisation, new supplier-ecosystems, shrinking margins, and sourcing/location considerations became increasingly important. Contract manufacturing operations like Uusikaupunki found themselves exposed.

In April 2022, Valmet Automotive announced change negotiations due to decreasing volumes: the Mercedes-GLC contract would end in June, and no immediate replacement was evident.

The local Finnish media in late 2025 reported the end of Mercedes-Benz production in Finland entirely — signalling the end of the car-assembly chapter in Uusikaupunki. Export allocation changes, tariffs, shifting transatlantic flows and competitive cost structures undoubtedly played a role in the OEM’s decision-making.

Strategic Pivot: Defence-industry Manufacturing in Sight

Facing the end of its main car-assembly contracts, Valmet Automotive did not choose closure. Instead, it repositioned itself as a high-tech contract manufacturer capable of producing electric-vehicle systems, battery packs, and, importantly, defence-industry hardware. Its website explicitly states a desire to extend expertise beyond automotive.

It is within this context that the LOI with Patria makes strategic sense. Patria’s surge in demand for armoured vehicles — driven by European defence investment, the Common Armoured Vehicle System (CAVS) programme, and security-of-supply imperatives — means capacity is at a premium. Patria currently manufactures in Hämeenlinna (Finland), Valmiera (Latvia), and uses technology-transfer partners in Poland and Slovakia. It has nearly 1,000 orders for its Patria 6×6 under CAVS.

By partnering with Valmet Automotive, Patria gains access to:

- An experienced serial-production facility with a high-quality track record

- A Finnish base with established infrastructure and a skilled workforce

- A degree of production redundancy and capacity expansion to meet demand

- Potential localisation bonus in defence-industrial supply chains

For Valmet Automotive, this opens a new manufacturing domain aligned with national defence, where contract manufacturing is less commoditised and more strategic.

For Defence, Business, and Policy

From Civil to Defence Manufacturing: Capability Reuse

Once the Uusikaupunki plant begins armoured-vehicle production, it will provide a compelling case of civil manufacturing assets being repurposed for defence production. The skills required — precise module assembly, integration of electronics, testing of complex systems, logistics, supply-chain management — overlap significantly between luxury-car contract manufacturing and armoured-vehicle production.

Industrial Resilience and National Security

Retaining high-value manufacturing in Finland is not just a business decision — it is strategic. From a defence-industry viewpoint, ensuring that critical production remains within NATO territory, under national control and with security of supply intact, is increasingly important in an era of geopolitical tension.

Business Investors and Industrial Strategy

For investors, the Valmet/Patria story indicates a growing trend: mature contract-manufacturing sites must pivot as automotive volumes drop and as defence/EV/battery sectors grow. The ability to reposition and reuse assets rather than shut them down can yield excellent returns.

Supply-chain and Employment Continuity

By keeping the Uusikaupunki plant operational — albeit shifting its product base — there is continuity for workers, for local suppliers, for logistics infrastructure. This should reduce structural adjustment costs and preserve human capital — all attractive from a policy and business risk viewpoint.

Open Questions

- Reconfiguration cost & capability shift: Transforming a passenger car assembly line into armoured-vehicle production is non-trivial. Changes in tooling, testing regimes, such as ballistics and blast resistance, manufacturing flows, supplier base and certification must all be addressed.

- Volume and scale: Automotive production is high-volume and highly standardised; armoured-vehicle production is lower volume but higher complexity. Valmet and Patria will need to align on economic models, cost-structures and investment.

- Strategic risk: Contract manufacturing in defence sector carries different risks, such as political, export controls and budget volatility, compared to automotive.

- Workforce and culture: The workforce is used to precision passenger-car manufacturing; defence manufacturing emphasises modularity, field spare-parts, customisation and long lifecycles. Transition in workforce culture will be needed.

- Supply-chain interplay: Defence production requires specialised components, such as armour, sensors and weapon mounts, with different logistics and security requirements compared with automotive supply-chains.

- Market timing and competition: Many European countries are ramping defence capacity; competing sites (Poland, Czech Republic, etc) may offer cheaper labour or incentives. Finland must offer something unique to maintain industrial advantage.

Emerging Trend in European Defence Industry

The Valmet–Patria partnership is consistent with emerging trends in European defence-industry policy. As European states invest heavily in land systems, modular armoured vehicles and production sovereignty, they prefer domestic manufacturing or at least trusted manufacturing partners within NATO.

Finland, with its skilled workforce, secure logistics network, and location outside of heavy labour-cost competition, but with competitive productivity, becomes an attractive anchor for manufacturing high-tech defence products. Moreover, repurposing existing high-end manufacturing infrastructure rather than building from scratch is cost-efficient and fast.

Automotive contract manufacturing sites all over the World may represent latent defence-industry assets — and that industrial policy which recognises this dual-use potential may yield both economic and security dividends.

If the Patria-Valmet collaboration proceeds to full agreement, the geography of land-system production in Europe will have a new chapter: one in which a Finnish coastal town becomes home to battlefield vehicles rather than luxury cars.

The armoured hulls may replace leather seats and infotainment screens, but the core manufacturing capability — high-precision assembly, modular systems integration, export orientation — remains unchanged.

Finland never built its own car brand, but with CAVS program and the new model TRACKX, Patria’s armoured vehicles are becoming more known around the World.

Read More:

- Patria: Patria signs a Letter of Intent with Valmet Automotive to join in armoured vehicle production and testing

- Valmet Automotive: 50 years of Finnish car manufacturing

- SaabPlanet: The Last Saab Delivered by Valmet Automotive

- Wikipedia: Saab 900

- UKSaabs forum: All Saab 900/9-3 Cabriolets from 1986 to 2003 were produced at Uusikaupunki

- Saabisti: Rare Saabs – The Finnish Specials

- Wikipedia: Saab 96

- Wikipedia: Saab 99

- Wikipedia: Saab 90

- Wikipedia: Saab 9000

- SaabBlog: Saab 9-3 Cabriolet

- YouTube: When The World’s Fastest FWD Sport Sedans Were Secretly The Same Car

- Wikipedia: Valmet Automotive (in Finnish)

- Influx/AdrianFlux: The Quiet Collaborator: Valmet Automotive

- Vintage Manuals: Saab 99

- Vintage Manuals: Saab 1968-73 95 and 96 V4; Sonett III Brochures

- Saab95net: Brochures,tests,+articles

- AutoBrochures: 9000 (1994)