For decades, the technological level of China’s defence equipment has been catching up with the Western world. In certain areas, China may have even surpassed the West. An important aspect of defence materials is that their quality must be sufficient and their cost manageable to enable acquisition in significant quantities

If your adversary can produce comparable quality products at a lower price, they become a serious threat. If that adversary also has a larger economy, you could find yourself in serious trouble. One way to investigate a narrow sector of quality development within China’s defence industry: ballistic aramid fibre composite helmets. They are inexpensive, but are they any good?

Helmets and Matrix

Ballistic composite helmets used by armies worldwide are primarily designed to stop fragments. They can also halt handgun threats and rifle-calibre bullets fired from a distance. Bullets carry more energy and momentum than fragments, potentially causing head injuries due to excessive backface deformation (BFD).

Firearms expert Mikko Anttila test-fired two Chinese aramid fibre composite helmets for Nordic Defence Review. Both helmets were priced at just under €300, placing them in the “economy” ballistic helmet category.

The first helmet featured woven aramid fibre fabrics in a thermoplastic matrix, giving the ballistic shell a whitish appearance. The matrix binds the reinforcing fibres together. This helmet was rated NIJ IIIA (0101.04 standard), capable of stopping 9x19mm rounds at submachine gun velocities and .44 Magnum rounds.

The second helmet, a newer generation model, utilized a thermoset polymer matrix with aramid fibre reinforcement. It was also rated NIJ IIIA.

Both helmets had basic interior padding and fitting systems. We did not evaluate the effectiveness of their padding in trauma reduction. Helmet padding is crucial for energy absorption and for mitigating injuries caused by blast overpressure waves, which can travel beneath the helmet in an explosion and cause head trauma.

Thermoset or Thermoplastic?

Thermoset resins, once hardened, cannot be reshaped with heat. Their structure is permanent. In contrast, thermoplastic polymers can be re-moulded with heat.

Thermoset matrix helmets are more rigid, with less flexibility, which lowers backface deformation. However, they are heavier for a given level of protection because the fibres cannot move as freely to absorb energy.

Thermoplastic matrix helmets are more flexible, offering better energy absorption at the cost of increased backface deformation. They are also easier to manufacture. Each material type has its pros and cons, highlighting the need for hybrid helmets.

Test Calibres

The helmets were tested with the following calibres: .22 Long Rifle, 9x19mm Parabellum, .357 Magnum, and .44 Magnum. An NIJ IIIA-rated helmet should stop all of these calibres. However, our focus was not on penetration resistance but on the degree of backface deformation, as excessive deformation increases the risk of head injury.

We did not use fragment-simulating projectiles (FSPs), which are necessary for assessing military helmets. Instead, we evaluated these helmets as if they were for law enforcement, which faces greater threats from handguns than from fragments.

Results: Significant Differences in Backface Deformation

For comparison, we referenced previous tests conducted on a BAE Systems Gen. II Advanced Combat Helmet (ACH). This helmet demonstrated excellent performance in minimising backface deformation and handling impacts from 9x19mm and .357 Magnum rounds near the rim.

The Chinese helmets successfully stopped all calibres tested. However, there were significant differences in backface deformation between the two.

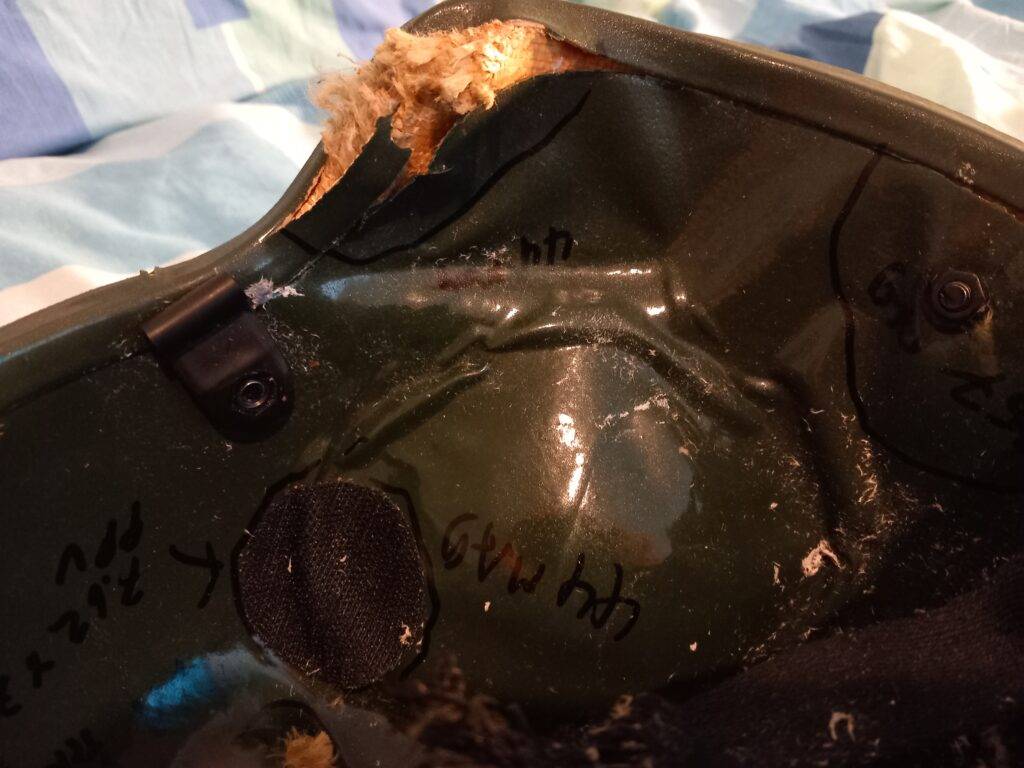

The thermoplastic matrix helmet performed poorly. Even 9x19mm rounds caused excessive bulging of the ballistic shell, to the extent that the helmet could no longer be worn after a few hits. In some cases, a 9x19mm round exited through the rim. Backface deformation from .357 Magnum rounds was nearly as severe as that caused by .44 Magnum rounds on the ACH helmet, highlighting the thermoplastic helmet’s substandard performance.

The thermoset helmet, on the other hand, was a pleasant surprise. It performed comparably to the U.S. ACH helmet, managing impacts close to the rim from 9x19mm and .357 Magnum rounds. However, a .44 Magnum round near the rim proved too much, resulting in penetration. Encouraged by its performance, we tested it with a 7.62x25mm Tokarev TT round, which it successfully stopped (with a soft-core bullet).

The Chinese thermoset helmet’s performance was comparable to the ACH helmet, whereas the thermoplastic helmet fell short.

Danger or Not?

Ballistic helmets are just one small part of military equipment. China has been catching up with the West in other areas such as aviation, naval capabilities, and drone warfare.

Our ballistic testing demonstrated that China could produce aramid fibre composite helmets comparable to Western standards at about half the price. The Chinese helmets we tested retailed for under €300, whereas similar European-made helmets cost nearly €600, despite being manufactured in Eastern Europe.

China’s ability to produce cost-effective ballistic helmets poses a concern. If this trend continues, the commercial market for such equipment could shift eastward—if it hasn’t already.